In recent years, the global manufacturing landscape has increasingly recognized the dominance of Chinese industry, particularly in the production of high-quality brushed motors. According to a report by MarketsandMarkets, the global brushed motor market is projected to reach USD 5.9 billion by 2025, with significant contributions from China due to its advanced production capabilities and cost-effective solutions.

Chinese manufacturers have not only excelled in domestic markets but have also strengthened their export capabilities, making them leaders in this sector. With a focus on innovation and quality, China is poised to unleash its global potential, establishing itself as the preeminent supplier of brushed motors that cater to various applications, from automotive to consumer electronics. This surge in production is a testament to the country's commitment to meeting the increasing demand for efficient and reliable motor solutions worldwide.

The rise of Chinese manufacturing has profoundly transformed the global economic landscape, positioning China as a pivotal player in various industries, particularly in the production of high-quality brushed motors. According to a report from the China Machinery Industry Federation, the country has maintained a leading position in the manufacturing sector, accounting for nearly 28% of global manufacturing output in 2022. This significant share highlights not only the scale of Chinese manufacturing but also its growing sophistication and innovation.

As manufacturers increasingly focus on quality and efficiency, sectors like automotive and consumer electronics have seen a dramatic shift towards Chinese-made products. A recent study by the McKinsey Global Institute projects that China's industrial automation will reach a market value of over $157 billion by 2030, underscoring the technological advancements driving efficiency in production. Furthermore, the global demand for brushed motors, which are crucial for applications ranging from household appliances to electric vehicles, has spurred Chinese companies to enhance their production capabilities. In the wake of these trends, international collaborations and investments are expected to further bolster China's manufacturing capabilities, solidifying its status as an essential hub in the global supply chain.

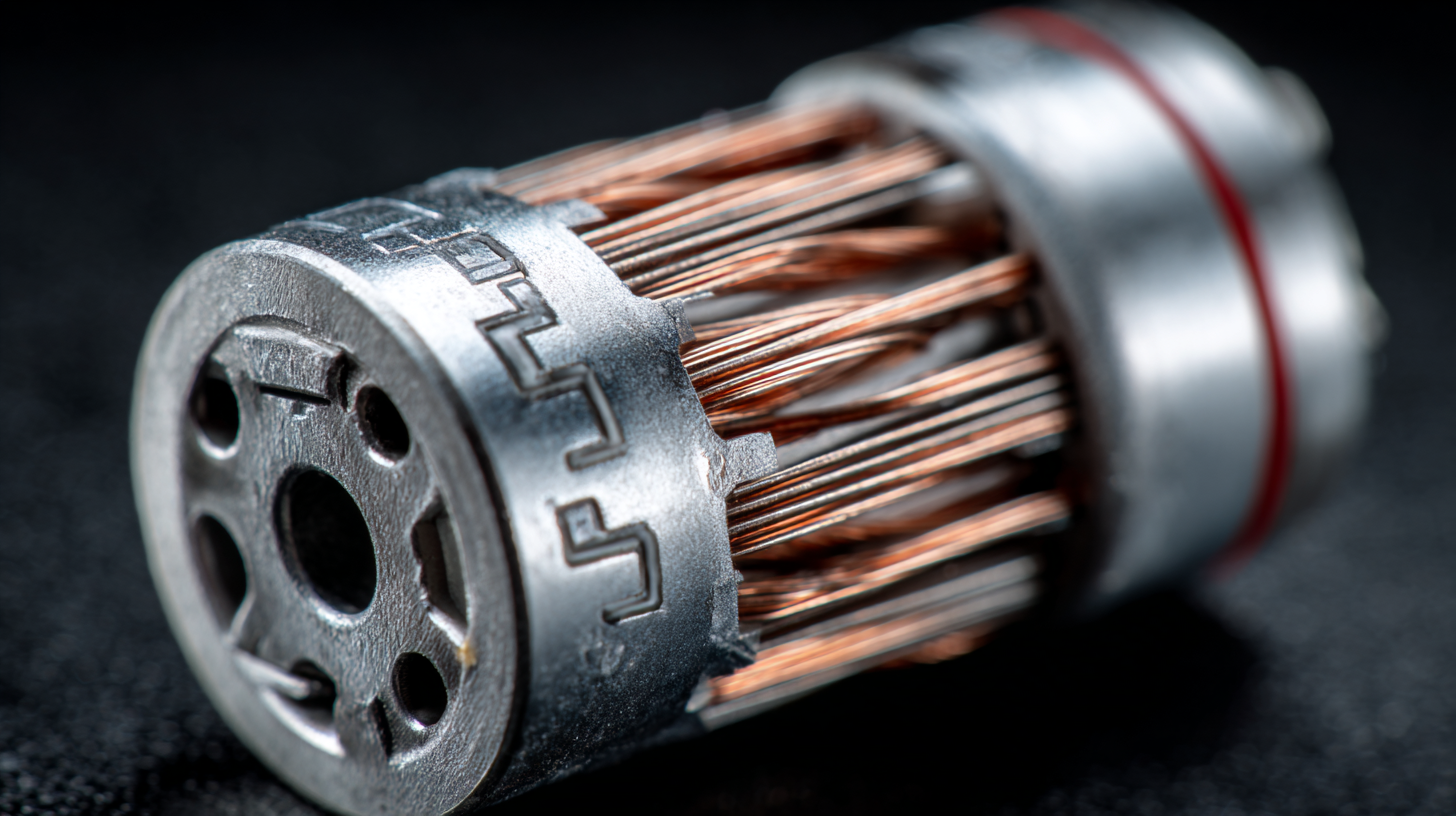

Understanding the advantages of best brushed motors is essential for unlocking the full potential of Chinese manufacturing. Brushed motors, while often overshadowed by their brushless counterparts, continue to offer unique benefits that enhance their appeal in various applications. One of the key advantages is their straightforward construction, which allows for easier implementation in manufacturing environments. This simplicity can translate into lower costs, making them an attractive option for producers looking to maintain quality while optimizing their budgets.

In high-performance scenarios, such as in electric vehicles, brushed motors have demonstrated their ability to deliver powerful performance. Recent advancements have highlighted how tuning techniques can enhance their efficiency, allowing more power to be extracted where needed. This attribute is particularly useful in competitive industries, where maximizing output can differentiate products in the market. As manufacturers explore innovations in brushed motor technology, the combination of performance and cost-effectiveness can position them as a compelling choice in the evolving landscape of global manufacturing.

The evolution of brushed motor technology is pivotal in enhancing the efficiency and reliability of Chinese manufacturing. Recent innovations focus on optimizing motor designs to improve performance while reducing costs. One significant advancement is the implementation of high-grade materials that minimize wear and tear, leading to longer lifespans and enhanced productivity. Manufacturers are also adopting advanced winding techniques, which allow for greater torque outputs and operational efficiencies. This not only supports the growing demand for durable motor solutions but also aligns with sustainability initiatives by reducing material waste.

Moreover, smart technology integration in brushed motors is transforming manufacturing practices. With the rise of Industry 4.0, these motors are being equipped with sensors and IoT capabilities that facilitate real-time monitoring and predictive maintenance. This shift not only reduces downtime but also enhances operational transparency and decision-making processes. Chinese manufacturers are at the forefront of this technological revolution, harnessing these innovations to optimize supply chains and boost their global competitiveness. By embracing these advancements, the Chinese manufacturing sector can unleash its full potential, positioning itself as a leader in the global marketplace.

In the fast-evolving landscape of global manufacturing, optimizing production efficiency is crucial for Chinese factories aiming to maintain a competitive edge. The introduction of best brushed motors has become a game-changer, significantly enhancing the operational capabilities of manufacturing processes. These motors are designed to deliver superior torque, rapid acceleration, and reliable performance, allowing factories to streamline workflows and reduce downtime. By integrating these advanced motors into their production lines, manufacturers can enhance their output with precision and speed.

Moreover, the implementation of smart manufacturing practices alongside these innovative brushed motors further amplifies efficiency. Utilizing data analytics and automation, factories can monitor performance in real-time, identifying bottlenecks and optimizing resource allocation. This synergy not only improves the quality of products but also reduces energy consumption and material waste, aligning with global sustainability goals. As China continues to position itself as a leader in manufacturing, leveraging cutting-edge technology like brushed motors will be key in unlocking their full potential and setting new standards for productivity.

| Factory Location | Brushed Motor Type | Monthly Production (Units) | Production Efficiency (%) | Employee Count |

|---|---|---|---|---|

| Shenzhen | Small DC Motor | 50,000 | 92 | 150 |

| Guangzhou | Standard Brushed Motor | 30,000 | 88 | 120 |

| Hangzhou | High Torque Motor | 20,000 | 85 | 80 |

| Nanjing | Miniature Brushed Motor | 45,000 | 90 | 180 |

| Wuhan | Precision Brushed Motor | 15,000 | 87 | 70 |

The global demand for efficient and versatile brushed motors is on the rise, driven by rapid advancements in technology and an increasing need for reliable power sources across various industries. Current estimates from the International Motor Industry Federation indicate that the global brushed motor market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028, underscoring the immense potential for Chinese manufacturers to expand their global footprint. By leveraging their established manufacturing capabilities and focusing on innovation, Chinese companies can become leaders in this critical sector.

To effectively expand their global reach, Chinese manufacturers should adopt strategies that emphasize collaboration and technology transfer. Forming strategic partnerships with international firms can provide access to new markets and supply chain efficiencies. Additionally, investing in research and development can foster the creation of advanced brushed motors that meet international quality standards. Reports from Frost & Sullivan highlight the necessity for continuous innovation, as consumer preferences increasingly tilt toward energy-efficient and sustainable products. By aligning their production processes with these trends, Chinese manufacturers can not only enhance their competitiveness but also fulfill the growing global demand for high-performance brushed motors.