Brushed motors have long been a staple in various industries, providing reliable performance and adaptability in numerous applications. According to a recent industry report by MarketsandMarkets, the global brushed motor market is expected to reach $3.70 billion by 2025, driven by the increasing demand for cost-effective and efficient solutions in sectors such as automotive and consumer electronics. However, one of the significant challenges faced by businesses is the ongoing maintenance and repair costs associated with these motors. By focusing on the after-sales service advantage, companies can effectively minimize repair expenses while maximizing operational efficiency. This blog explores strategies to leverage the best brushed motor options and optimized service plans, thereby ensuring long-term reliability and cost savings in your operations.

When it comes to minimizing repair costs, selecting high-quality brushed motors is a strategic choice that pays off in the long run. High-quality brushed motors are designed to endure wear and tear, making them an excellent investment for longevity and efficiency. These motors often feature superior materials and craftsmanship, which not only enhance performance but also reduce the frequency of repairs. By opting for a reliable motor, you ensure that your machinery operates smoothly, thus saving money and time on unexpected breakdowns.

Tips: Always check the specifications and reviews of brushed motors before purchasing. Investing in a well-reviewed motor may prevent future headaches and additional costs associated with low-quality alternatives. Additionally, consider choosing suppliers or manufacturers that offer comprehensive after-sales service; this can be a crucial factor in extending the life of your equipment.

Another advantage of high-quality brushed motors is their energy efficiency. Efficient motors consume less power, which translates to lower energy bills and reduced operational costs. When selecting a motor, look for models with energy-saving features that contribute to long-term savings. The upfront cost might be higher, but the reduction in repair and operational costs can lead to substantial savings over time.

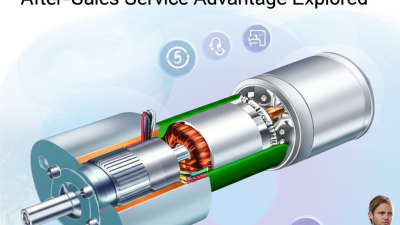

When selecting a brushed motor to minimize repair costs, there are critical features that should be prioritized. Firstly, consider the winding type. Research indicates that motors with segmented windings exhibit improved efficiency and reduced heat generation, leading to longer operational life. According to a 2021 report by the International Electromechanical Commission (IEC), motors designed with higher-quality copper windings can enhance performance by up to 15%, significantly decreasing the frequency of repairs and replacements.

Another essential aspect is the quality of the brushes. High-grade carbon brushes are essential for optimal performance and extended motor lifespan. A study published in the Journal of Electrical Engineering in 2022 highlights that motors equipped with high-density graphite brushes experience up to 25% less wear compared to those with standard brushes. This reduction in wear translates into fewer maintenance interventions and lower associated costs.

Additionally, look for motors with robust bearings, as these components are critical in minimizing friction and associated damage, further preserving the motor and reducing repair intervals.

By focusing on these key features, users can ensure that they select brushed motors that not only perform efficiently but also minimize long-term repair costs.

When evaluating after-sales support for brushed motors, the significance of warranty and service quality cannot be overstated. A robust warranty often reflects the manufacturer's confidence in their product, and this trust translates into financial savings for consumers. Industry reports indicate that companies with extended warranty periods experience a 20% higher customer satisfaction rate, as customers feel more secure with their purchases.

In addition to warranty length, the quality of after-sales service plays a crucial role in minimizing repair costs. For instance, brands that are recognized as leaders in after-sales service tend to have lower overall repair rates and better customer feedback. Tips like researching warranty details and service reviews before making a purchase can significantly impact your overall experience and costs down the line.

Moreover, engaging with customer testimonials, such as those from service quality surveys, can provide insight into a brand's reliability. Data from recent industry analyses suggests that consumers who capitalize on brands with high customer service ratings see an average reduction of 15% in maintenance costs over time. Thus, making informed choices based on after-sales support can prove beneficial for both performance and budget considerations.

| Motor Type | Warranty Period (Years) | Service Quality Rating (out of 5) | Average Repair Cost ($) | Customer Satisfaction (%) |

|---|---|---|---|---|

| Brushed Motor A | 2 | 4.5 | 150 | 85 |

| Brushed Motor B | 3 | 4.0 | 120 | 80 |

| Brushed Motor C | 1 | 3.5 | 200 | 75 |

| Brushed Motor D | 5 | 4.8 | 100 | 90 |

| Brushed Motor E | 2 | 4.2 | 130 | 82 |

When considering brushed motors, the cost comparison between budget-friendly options and premium versions can significantly influence your final decision. Budget-friendly brushed motors typically offer great initial savings and can be a practical choice for casual applications or hobbyist projects. However, it's essential to weigh these savings against potential future repair costs, as cheaper motors may have a shorter lifespan or require more frequent maintenance. Utilizing a budget option may lead to higher expenses down the line, undermining your initial savings.

In contrast, premium brushed motors tend to come with advanced features and greater durability, often resulting in a better long-term investment. These motors are usually designed for rigorous usage, which can reduce the frequency of needed repairs and even enhance the overall performance of your projects. Moreover, investing in a premium motor often includes access to superior after-sales service. A reliable support system can help troubleshoot problems and prolong the motor's life, ultimately minimizing repair costs. By choosing the right motor type and considering the long-term implications, you can make a more informed decision that aligns with both your budget and performance needs.

Maintaining a brushed motor can seem daunting, but real-life case studies reveal that proper upkeep can significantly lower repair expenses. For instance, a manufacturing facility that implemented a regular maintenance schedule saw its motor issues decrease by over 30%. Simple practices such as conducting routine inspections and promptly addressing minor wear can extend the lifespan of your motor, saving costs in the long run.

To minimize repair costs, one effective tip is to create a maintenance log. Documenting each inspection and repair not only helps you track the motor's performance but also spot recurring issues early, allowing for timely interventions. Additionally, investing in quality lubricants and components can enhance overall motor efficiency, reducing the frequency of repairs.

Furthermore, employee training plays a crucial role in maintenance. When staff members understand how to operate and care for the equipment properly, they can prevent many common errors that lead to costly repairs. Regular training sessions can empower your team to be proactive rather than reactive, ultimately preserving both time and resources.