Hollow cup motors are increasingly recognized for their efficiency and compact design, making them a popular choice in various applications, from consumer electronics to industrial machinery. According to recent industry reports, the global market for miniature motors, including hollow cup motors, is projected to reach $7.5 billion by 2025, reflecting a growing demand for high-performance, cost-effective solutions. This blog aims to provide a tutorial on maximizing the value of hollow cup motors through effective repair strategies and exceptional customer support. By addressing common repair challenges and exploring how quality customer service can enhance the lifespan and efficiency of these motors, we hope to empower businesses to make informed decisions that not only reduce operational costs but also improve overall performance in their applications.

As we approach 2025, advancements in hollow cup motor technology are setting the stage for significant enhancements in various applications, including humanoid robots. With the growing demand for dexterous hands and intricate movements, optimizing hollow cup motors is crucial. These motors are becoming integral to robotics, enabling smoother and more precise control. The push for humanoid robots to fulfill final-mile delivery services reflects the broader trend of integrating advanced technology into everyday tasks.

Tip: When selecting a hollow cup motor, consider its torque and speed specifications to ensure it meets the requirements of your specific application. Pay attention to the feedback mechanisms available for these motors, as they can greatly enhance precision in robotic movements.

Furthermore, exceptional customer support plays a key role in maximizing the value of hollow cup motors. As robotics manufacturers aim to scale production, continuous dialogue with suppliers can help address challenges promptly and ensure efficient repairs. This proactive approach not only reduces downtime but also fosters innovation in design and functionality.

Tip: Establish a routine maintenance schedule for hollow cup motors to extend their lifespan and maintain performance. Regular check-ups can prevent minor issues from escalating into costly repairs.

Hollow cup motors are renowned for their compact size and high efficiency, making them indispensable in various applications. However, like any other mechanical components, they are prone to wear and tear over time. To maximize their value, implementing cost-effective repair strategies is crucial. One effective approach is routine maintenance, which can help identify potential issues before they escalate. Regularly checking for signs of wear, inspecting wiring, and ensuring proper lubrication can extend the lifespan of the motor, reducing the need for costly replacements.

Another strategy involves utilizing specialized repair services that focus on hollow cup motors. These services often provide a thorough analysis of the motor’s condition and can offer tailored repair options that may include part refurbishment or replacement. Investing in high-quality repair solutions not only restores the motor’s performance but also enhances its efficiency, ensuring that your operations remain smooth and cost-effective. Furthermore, exceptional customer support from repair providers can guide customers through maintenance protocols and repair processes, fostering a partnership that simplifies future repairs and keeps downtime to a minimum.

The hollow cup motor industry is undergoing significant transformations, largely driven by evolving customer support trends. As manufacturers strive to enhance their products, the demand for exceptional customer service has become a focal point. Companies are increasingly recognizing that superior customer support not only fosters brand loyalty but also provides valuable insights into the users' experiences and expectations. By actively engaging with customers through feedback mechanisms and responsive communication, businesses can tailor their offerings to better meet the needs of their clients.

Another notable trend is the integration of technology in customer support channels. With the rise of artificial intelligence and automation, hollow cup motor manufacturers are now able to offer 24/7 support through chatbots and online resources. This not only streamlines the assistance process but also allows companies to address customer inquiries more efficiently. As a result, customers enjoy quicker resolutions and feel more valued, which in turn boosts their overall satisfaction with the product and company. By prioritizing these support trends, businesses in the hollow cup motor industry can maximize value and foster long-term relationships with their clientele.

In 2025, the market for hollow cup motors has witnessed significant advancements, making it essential to maximize value through informed choices. When comparing the top models in the industry, factors such as efficiency, size, and torque must be carefully considered. Leading brands this year have focused on producing lightweight and compact designs without compromising performance, greatly enhancing their suitability for various applications, from robotics to consumer electronics.

Tip: When selecting a hollow cup motor, always analyze the specifications in relation to your project's needs. Consider how the weight and dimensions will affect installation and overall functionality. Additionally, ensure that the motor’s RPM and torque ratings align with the performance expectations of your application.

As you conduct your comparative analysis, remember to evaluate customer support and repair options offered by manufacturers. Superior customer service can make a substantial difference, especially when issues arise or if you require replacements. Researching user reviews and seeking recommendations can help you find a motor that not only meets your performance criteria but also comes with reliable support.

Tip: Don’t hesitate to reach out to manufacturers and ask about their repair policies, warranty coverage, and any ongoing support services. This proactive approach can save you time and costs in the long run while ensuring your investment in hollow cup motors pays off.

Hollow cup motors have emerged as a crucial component in modern machinery, driving operational efficiency across various industries. According to a report by MarketsandMarkets, the global market for miniature motors, including hollow cup motors, is expected to reach USD 6.4 billion by 2025, growing at a CAGR of 8.2%. This growth is driven by the demand for precise control in applications such as robotics, aerospace, and medical devices, where performance and reliability are paramount.

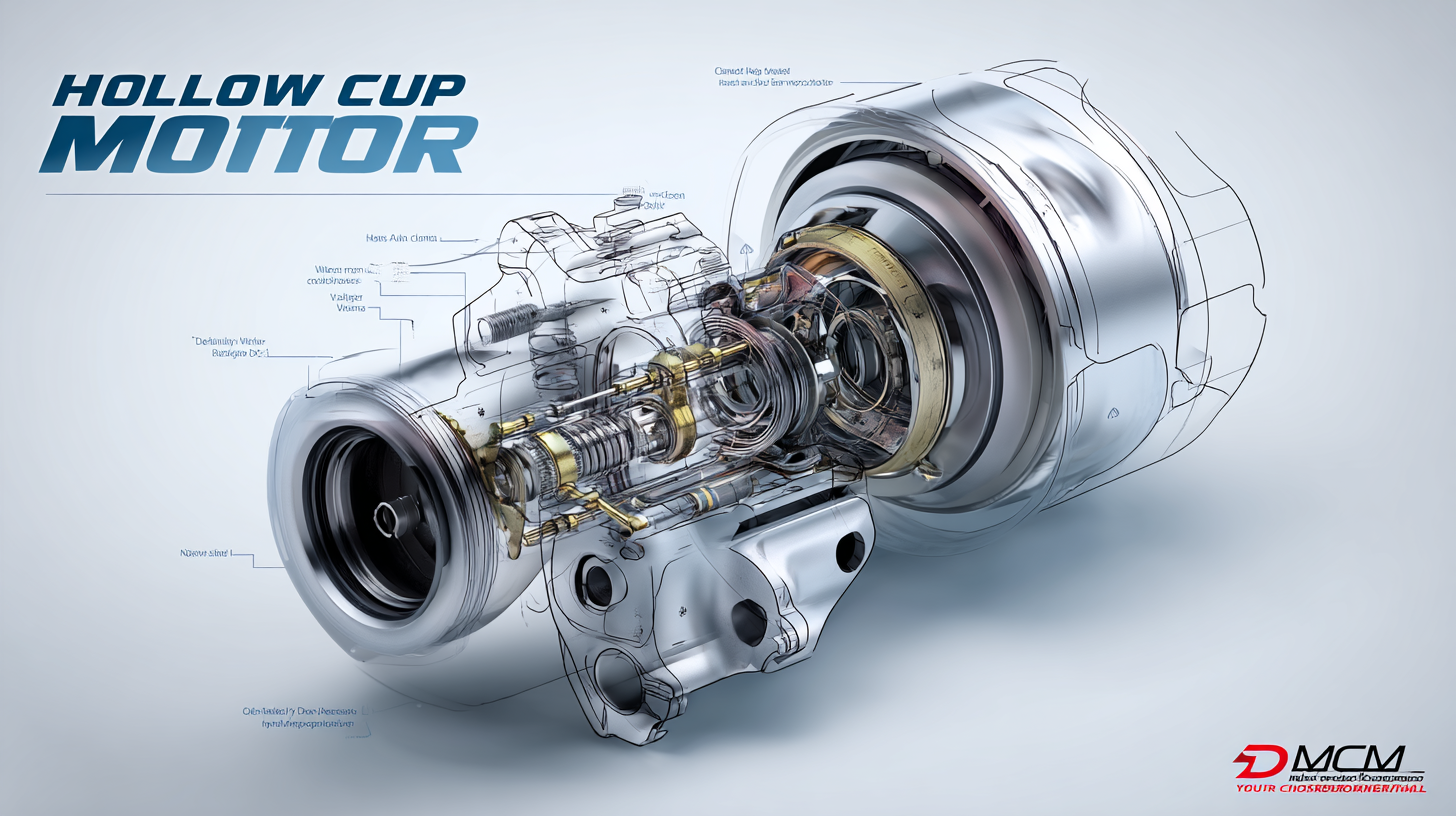

Maximizing operational efficiency with hollow cup motors involves understanding their unique advantages. Unlike conventional motors, hollow cup motors are designed with a compact form factor and high torque-to-weight ratio. Research indicates that these motors can achieve up to 50% more efficiency compared to traditional designs, making them ideal for applications where space and energy consumption are critical. Moreover, their low operating noise and vibration levels enhance the overall performance of equipment, thereby reducing wear and tear, which in turn lowers maintenance costs.

Investment in cost-effective repairs and exceptional customer support can further enhance the value derived from hollow cup motors. By ensuring timely maintenance and providing access to skilled technicians, businesses can significantly prolong the lifespan of these motors. According to a study from the National Institute of Standards and Technology (NIST), proactive maintenance strategies can reduce operational costs by up to 30%. This not only contributes to better resource allocation but also reinforces the importance of quality customer support in optimizing the performance of hollow cup motors.