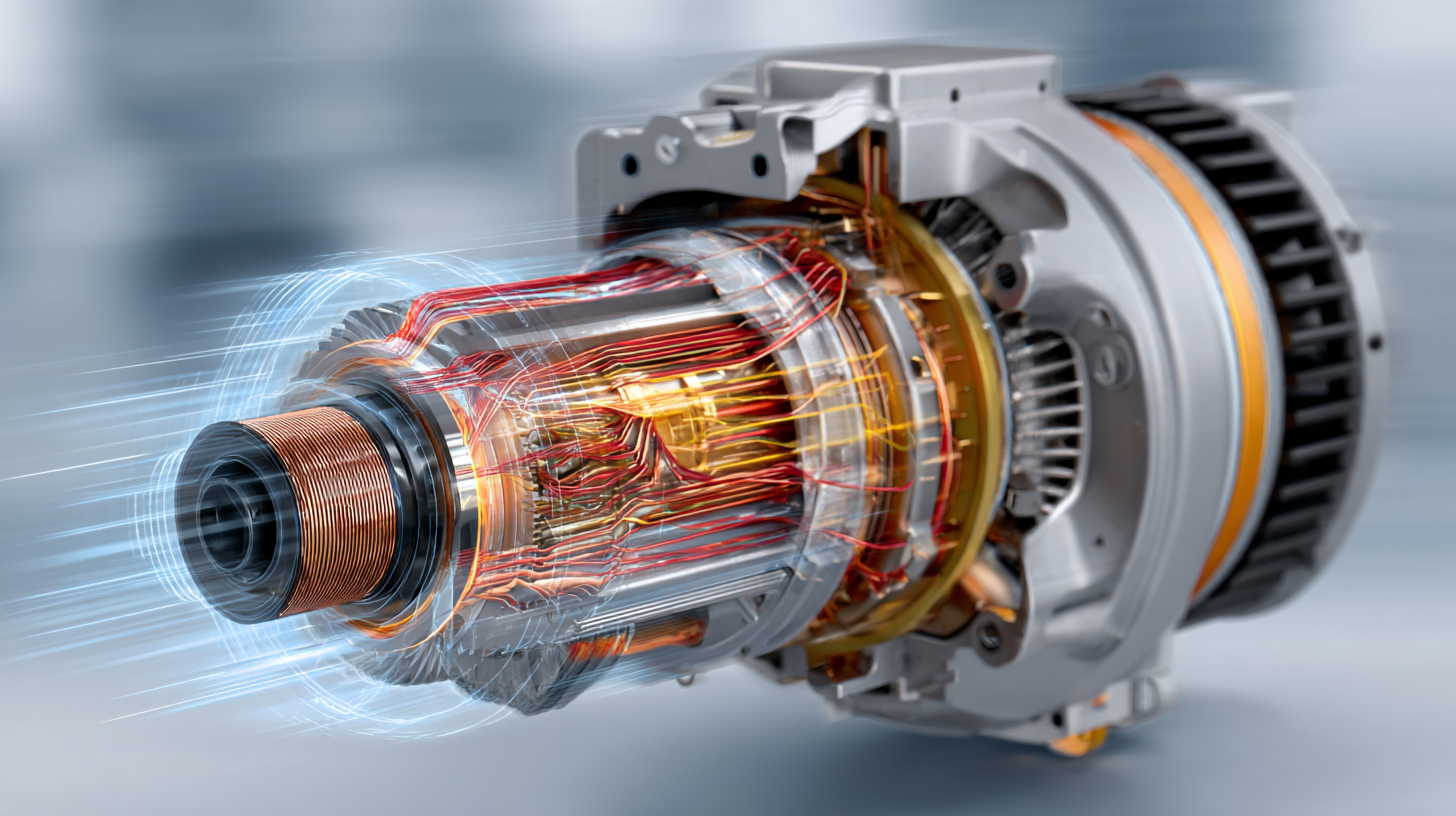

With the rapid advancement of technology and the continuous push for efficiency, brushless motors have emerged as a critical component in various industries. According to a recent market research report by Research and Markets, the global brushless motor market is expected to reach USD 36.2 billion by 2025, growing at a CAGR of 9.5%. This significant growth is fueled by the increasing demand for energy-efficient and durable motor solutions across sectors such as automotive, industrial automation, and consumer electronics. As industries strive to enhance performance while reducing energy consumption and maintenance costs, understanding the best industry standards for brushless motors becomes essential. This blog will explore the key factors driving the adoption of brushless motors, alongside real-world applications that demonstrate their transformative impact across different fields.

When selecting brushless motor suppliers, understanding the essential qualities that define their reliability and performance is crucial. According to the International Electrotechnical Commission (IEC), brushless motors are projected to experience a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This growth emphasizes the need for industry leaders to screen suppliers rigorously to ensure they meet high-quality standards.

One key factor to consider is the supplier's capability in providing customized solutions tailored to specific applications. Research from MarketsandMarkets highlights that customization can enhance motor performance by up to 20% in certain applications, making it an indispensable aspect when working with top suppliers. Additionally, the level of technical support and after-sales service offered by suppliers influences long-term partnerships. Suppliers who invest in R&D, evidenced by their patent filings—which increased by 40% in the last five years according to a study by Deloitte—demonstrate a commitment to innovation, further solidifying their status as reliable partners in the industry.

When selecting a brushless motor supplier, evaluating their experience and industry expertise is crucial. Established suppliers bring a wealth of knowledge and an extensive portfolio of projects that demonstrate their capability and reliability. This experience often translates into a deeper understanding of customer needs, enabling them to offer tailored solutions that optimize performance and efficiency. For industries ranging from aerospace to consumer electronics, working with a supplier who has proven experience can significantly impact product quality and time-to-market.

Moreover, industry expertise goes beyond mere technical know-how. Suppliers who specialize in specific applications can provide insights into the latest technologies and industry trends, allowing clients to remain competitive. This expertise can be particularly valuable in sectors that require high precision and innovation, where staying ahead of technological advancements is essential. By assessing a supplier’s background and their track record in handling similar projects, companies can make informed decisions that enhance their operational efficiency and product development timelines.

| Key Factor | Description | Importance Rating (1-5) | Industry Standard | Typical Applications |

|---|---|---|---|---|

| Efficiency | The ratio of output power to input power, indicating energy loss. | 5 | IE3 or higher | Electric vehicles, drones |

| Size and Weight | Compact design for easy integration in various systems. | 4 | NEMA or IEC standards | Portable tools, robotics |

| Durability | Resistance to wear and tear over prolonged use. | 4 | ISO 9001 | Industrial machinery, HVAC |

| Control Precision | Ability to accurately control speed and position. | 5 | IEC 61508 | CNC machines, robotics |

| Cost of Ownership | Total cost including purchase price and maintenance. | 3 | N/A | Consumer electronics, automotive |

When selecting vendors for brushless motors, understanding supply chain reliability becomes paramount. According to a recent report by McKinsey & Company, supply chain disruptions have increased by 50% over the last five years, prompting companies to prioritize stability when forging partnerships. This reliability is particularly critical in the high-tech sector, where a 2021 study from Gartner indicated that 75% of manufacturers consider supply chain resilience a key factor in vendor selection. By ensuring that their suppliers can maintain consistent operations, businesses can better mitigate risks associated with production delays.

Moreover, an analysis from the Institute for Supply Management highlights that companies with robust supply chain strategies are 40% more likely to outperform their competitors in revenue growth. For brushless motor manufacturers, factors such as transparency, lead time predictability, and supplier financial health are essential. Investing in suppliers that prioritize these elements not only enhances operational efficiency but also fosters innovation within the industry. As the demand for high-quality, reliable brushless motors intensifies, organizations must align their vendor selection processes with these critical supply chain drivers to remain competitive and responsive in the market.

The rapid evolution of brushless motors is largely driven by continuous innovation and technology adoption in the motor manufacturing industry. According to a recent report by Allied Market Research, the global brushless motor market was valued at $18.13 billion in 2021, and it is projected to reach $36.79 billion by 2031, growing at a CAGR of 7.5%. This robust growth emphasizes the industry's shift towards more efficient, durable, and versatile motor solutions.

One of the key factors propelling this adoption is the increased demand for energy-efficient technologies. As industries strive to meet stringent environmental regulations and reduce operating costs, brushless motors, known for their low energy consumption and minimal maintenance requirements, are becoming the preferred choice. Additionally, advancements in materials science and microcontroller technology enable manufacturers to produce more compact and powerful motors, further enhancing their appeal across various applications, from automotive to industrial automation. As the industry continues to innovate, the adoption of brushless motors is expected to accelerate, transforming the landscape of motor technologies.

Navigating compliance with industry standards has become a pivotal consideration in the selection of suppliers for brushless motors. As these motors see widespread adoption across sectors such as aerospace, automotive, and consumer electronics, adherence to established standards ensures both safety and performance. According to a recent report from the International Electrotechnical Commission (IEC), over 70% of manufacturers prioritize compliance with international standards, reflecting a growing trend toward quality assurance and reliability in their supply chains.

In evaluating suppliers, companies must consider key factors such as efficiency ratings, thermal performance, and electromagnetic compatibility. The global market for brushless motors is projected to reach $30 billion by 2028, driven by advancements in battery technologies and the rising demand for energy-efficient solutions. As highlighted in the recent Smithers report, 63% of industry leaders identify adherence to performance standards as a crucial component in their procurement strategy. By carefully selecting suppliers that meet these criteria, organizations can enhance their operational efficiency while minimizing risks associated with non-compliance and subpar product performance.