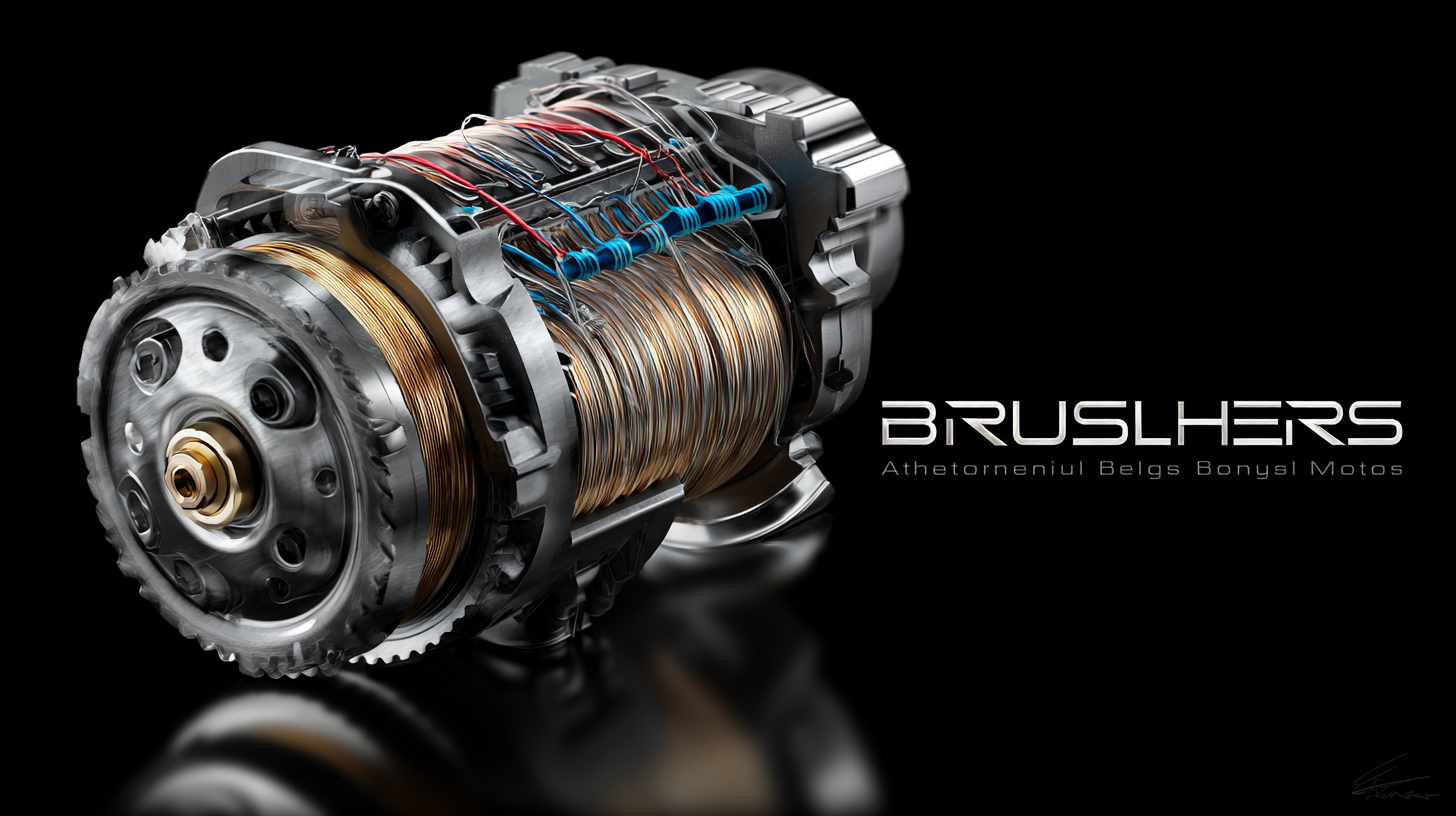

In recent years, the demand for high-performance Brushless Motors has surged, driven by advancements in technology and the increasing need for energy efficiency across various industries. According to a report by Fortune Business Insights, the global brushless motor market size is expected to reach USD 17.43 billion by 2027, expanding at a compound annual growth rate (CAGR) of 6.9% from 2020 to 2027. This growth is largely fueled by the rise of electric vehicles, robotics, and automation, where brushless motors play a crucial role in enhancing performance and reliability.

As manufacturers in China continue to enhance their production capabilities, their brushless motors are becoming increasingly competitive in the global market, showcasing a commitment to innovation and quality. This blog will explore alternative technologies that challenge conventional brushless motor designs, aiming to promote enhanced performance and efficiency in a rapidly evolving landscape.

When selecting a brushless motor, the reputation of the manufacturer plays a crucial role in ensuring enhanced performance and reliability. Established manufacturers often have a history of producing high-quality motors, which can provide customers with the confidence needed for their applications. A reputable manufacturer invests in research and development, leading to innovations and improvements that directly impact motor efficiency, durability, and overall performance. Consequently, their products are frequently subjected to rigorous testing, which helps to minimize the risk of failures during operation.

In addition to performance metrics, customer service and support are critical aspects influenced by manufacturer reputation. Reputable companies typically offer comprehensive warranties, detailed product information, and responsive customer support. This is especially important for businesses that rely on these motors for critical applications, where downtime can be costly. By prioritizing manufacturer reputation in the selection process, users can make informed decisions, ensuring that they not only receive a high-performing brushless motor but also ongoing support throughout the product's lifespan.

When evaluating brushless motor suppliers, it's essential to consider several key criteria to ensure the best fit for your needs. Firstly, the supplier's experience and industry reputation play a critical role. According to a 2021 market research report by Transparency Market Research, the global brushless motor market is expected to grow at a CAGR of 7.4%, highlighting the increasing demand for reliable and innovative motor solutions. A supplier with a proven track record can offer insights and advanced technologies that facilitate high-performance applications across various sectors, including automotive, aerospace, and consumer electronics.

Another important criterion is the quality certification of suppliers. ISO 9001 certification, for example, assures that a supplier maintains consistent quality management systems. Furthermore, the integration of Industry 4.0 practices is becoming vital in modern manufacturing. A report from Grand View Research notes that the adoption of IoT-enabled solutions in brushless motor production can significantly enhance efficiency and productivity by up to 30%. Suppliers who leverage such technologies not only provide better performance but also demonstrate their commitment to innovation and excellence in motor design and manufacturing.

In recent years, the demand for higher efficiency and performance in various applications has driven engineers to explore innovative alternatives to traditional brushless motors. While brushless motors have long been praised for their reliability and efficiency, new technologies are emerging that promise to surpass these conventional solutions. For instance, magnetic levitation motors leverage magnetic forces to eliminate friction, resulting in smoother operation and reduced wear on components, significantly enhancing longevity and performance.

Another promising alternative is the development of piezoelectric motors, which utilize the piezoelectric effect to produce motion with precision. These motors enable fine adjustments in applications that require high accuracy, making them ideal for robotics and aerospace technologies. Additionally, advancements in supercapacitor technology are combining with these alternative motor solutions to provide energy storage capabilities that can further enhance performance, allowing for faster acceleration and improved energy efficiency. As these innovative technologies continue to evolve, they present exciting opportunities for revolutionizing the way we think about motion and power in modern machinery.

| Technology Type | Efficiency (%) | Torque (Nm) | Speed (RPM) | Weight (kg) |

|---|---|---|---|---|

| Switched Reluctance Motor | 95 | 3.5 | 6000 | 4.0 |

| Permanent Magnet Synchronous Motor | 90 | 2.8 | 5000 | 3.5 |

| Interleaved Multi-Phase Motor | 92 | 4.2 | 5400 | 4.5 |

| Cored and Coreless Brushless Motor | 85 | 3.0 | 4500 | 2.5 |

| Axial Flux Motor | 93 | 5.0 | 7500 | 3.2 |

When selecting a brushless motor, understanding performance metrics is crucial to ensure optimal efficiency and functionality. Key metrics include torque-to-weight ratio, efficiency ratings, and thermal performance. For instance, a study by the Electric Propulsion Society indicates that motors with a high torque-to-weight ratio can enhance overall system performance by an impressive 20%, making them ideal for applications requiring quick accelerations and precise control.

Tip: Always look at the efficiency curve of the motor; a motor that maintains high efficiency across its operating range can significantly reduce energy consumption, leading to longer operational time and lower costs over time.

Another critical metric is thermal performance. As motors operate, heat generation can lead to reduced lifespan and failure. According to the International Journal of Machine Tool and Manufacture, a well-designed brushless motor can achieve thermal efficiencies of up to 95%. Choosing a motor with superior thermal management capabilities can mitigate risks associated with overheating and ensure sustained performance in demanding environments.

Tip: Consider implementing a cooling system if the application involves continuous high loads. Investing in proper thermal management can extend the motor’s operating life and enhance reliability.

The increasing focus on sustainability within the manufacturing industry has led brushless motor manufacturers to adopt various eco-friendly practices. These efforts not only reduce environmental impact but also enhance the overall efficiency of their production processes. For instance, many companies are investing in renewable energy sources to power their facilities, significantly cutting down on greenhouse gas emissions. This shift towards green energy is increasingly becoming a standard practice, reflecting a broader commitment to sustainability.

Moreover, manufacturers are re-evaluating their supply chains to source materials responsibly. The use of recycled materials and sustainable components is on the rise, allowing for a reduction in waste and promoting a circular economy. Companies are also implementing stricter regulations on waste management, ensuring that hazardous materials are disposed of properly and minimizing contamination in manufacturing processes. By focusing on sustainability, brushless motor manufacturers not only improve their reputation but also cater to a growing consumer base that values environmentally conscious practices.