In the rapidly evolving landscape of electric motors, understanding industry standards is crucial for selecting the best Brushed Motor tailored to specific applications. Recent reports indicate that the global market for brushed motors is projected to reach USD 19.8 billion by 2025, driven by increasing demand in sectors such as automotive, industrial machinery, and consumer electronics.

The benefits of using brushed motors, including simplicity, cost-effectiveness, and reliability, make them a popular choice for many applications, particularly where space is limited and ease of control is paramount. With various options available, navigating through the performance characteristics, longevity, and specific requirements of each motor type can be daunting. This blog aims to demystify the selection process and provide insight into how to effectively evaluate brushed motors to meet your unique needs.

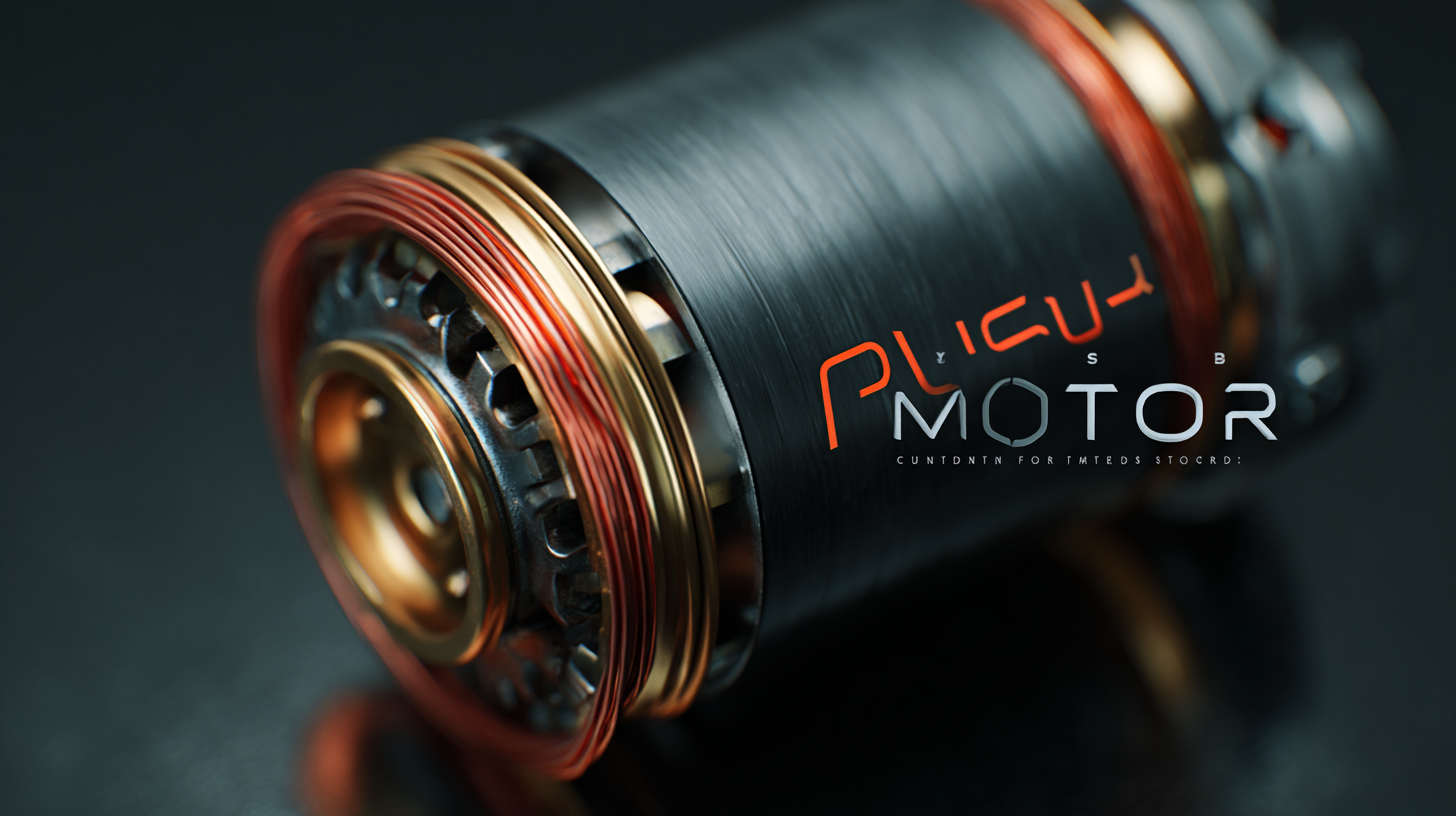

When exploring the world of brushed motors, it's essential to familiarize yourself with key terminology and concepts that define their performance and suitability for various applications. Brushed motors operate using a simple yet effective design that incorporates brushes and a commutator to transfer electrical energy to the motor windings. This direct contact facilitates seamless rotation but can also lead to wear over time. Understanding terms like "torque," "rpm," and "efficiency" is crucial for evaluating how well a motor will meet your needs.

Torque, for instance, measures the rotational force produced by the motor, which directly impacts how it can handle loads. Higher torque is often required for applications involving heavy lifting or fast acceleration. The revolutions per minute (rpm) metric provides insight into the speed capabilities of the motor, which is critical for processes requiring rapid movement. Lastly, efficiency indicates how well a motor converts electrical energy into mechanical energy, directly affecting the operating costs over time. By grasping these foundational concepts, you can make informed decisions when selecting the best brushed motor for your specific application.

When choosing the best brushed motor for your application, it is essential to consider various factors that align with your specific needs. The electric motor market is projected to grow significantly, with the demand for DC motors, in particular, expected to increase substantially by 2032. Such motors are categorized by their power source, application areas, and voltage ratings—ranging from low voltage (below 100V) to high voltage (above 1000V). Understanding these classifications can help in identifying the right motor type that fits your operational requirements.

The industry is currently witnessing a surge in innovation and product development, particularly in the context of electric vehicles and renewable energy applications. In fact, the demand for brushless motors has increased due to their efficiency and longer lifespan, propelling the market toward a projected compound annual growth rate (CAGR) of over 7% during the coming years. Furthermore, the rising integration of advanced technologies, such as motor drivers and controllers, is reshaping how motors are applied across industries, ensuring enhanced performance and reduced energy consumption. By aligning your motor choice with these trends, you can optimize both efficiency and cost-effectiveness in your projects.

When comparing motor types, brushed motors offer distinct advantages and disadvantages that are crucial for applications across various industries. One of the key benefits of brushed motors is their simplicity and cost-effectiveness. According to a report by the National Electrical Manufacturers Association (NEMA), brushed motors can be 30% less expensive than their brushless counterparts, making them an attractive option for budget-sensitive projects. Additionally, they provide reliable torque control, which is vital in applications like robotics and automotive systems.

However, the disadvantages of brushed motors cannot be overlooked. The friction caused by brushes leads to wear and tear, resulting in a shorter lifespan—often around 2,000 to 5,000 hours compared to 20,000 hours or more for brushless motors, as highlighted in a study by the International Electrotechnical Commission (IEC). Moreover, brushed motors typically exhibit lower efficiency due to energy losses from brush friction, with efficiency rates ranging from 70% to 85%, while brushless alternatives can achieve efficiencies above 90%. These factors make it essential for engineers and designers to carefully evaluate their specific needs when selecting a motor type for their applications.

When selecting a brushed motor for your application, evaluating performance specifications is crucial to ensure optimal functionality and longevity. One of the key parameters to consider is the motor's voltage rating, as this dictates the power supply needed for efficient operation. A motor operating at its designed voltage will perform best, providing the right balance between speed and torque. Additionally, it's essential to look at the current rating, which indicates how much load the motor can handle without overheating or causing damage.

Another important specification to analyze is the RPM (revolutions per minute) range, as this reflects the motor's speed capabilities. Depending on your application, you may require a motor that offers high-speed performance or one that provides more torque at lower speeds. Furthermore, consider the efficiency rating, which highlights how effectively the motor converts electrical energy into mechanical energy. Higher efficiency means less energy wasted as heat, resulting in better performance and reduced operational costs over time. By carefully evaluating these specifications, you can choose a brushed motor that perfectly aligns with your requirements, ensuring reliable and efficient performance in your projects.

When selecting a brushed motor, understanding industry standards and certifications is essential for ensuring compliance and reliability. Various organizations, including the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA), provide guidelines that help in assessing motor performance and safety. According to a 2022 report from MarketsandMarkets, the global brushed motor market is expected to reach $5.4 billion by 2027, driven by increasing demands for high-efficiency motors that meet strict energy regulations such as IEC 60034 and NEMA MG1. These standards ensure that the motors are not only efficient but also safe and reliable in various applications.

Compliance with industry standards is crucial, particularly for motors used in sensitive environments such as medical devices or aerospace applications. Certifications like UL (Underwriters Laboratories) and CE (Conformité Européenne) symbolize that a motor meets specific regulatory requirements, thus reducing risks associated with performance and safety. For instance, an industry survey highlighted that motors certified by UL demonstrate a failure rate 30% lower than non-certified counterparts, underscoring the importance of choosing a motor that adheres to rigorous standards. By prioritizing certified products, manufacturers can enhance operational safety and ensure quality, thereby establishing a competitive advantage in the market.