When it comes to selecting the right brushless motor for your application, understanding the various alternatives available is crucial. Brushless motors, known for their high efficiency and longevity, have become essential in numerous industries, from automotive to aerospace. According to a recent report by MarketsandMarkets, the global brushless motor market is expected to reach USD 25.4 billion by 2026, growing at a CAGR of 9.2%. This significant growth is driven by the increasing adoption of automation and robotics, as well as the demand for energy-efficient solutions. As businesses look to optimize performance while minimizing operational costs, exploring alternative types of brushless motors—such as inner rotor, outer rotor, and low voltage DC motors—becomes imperative.

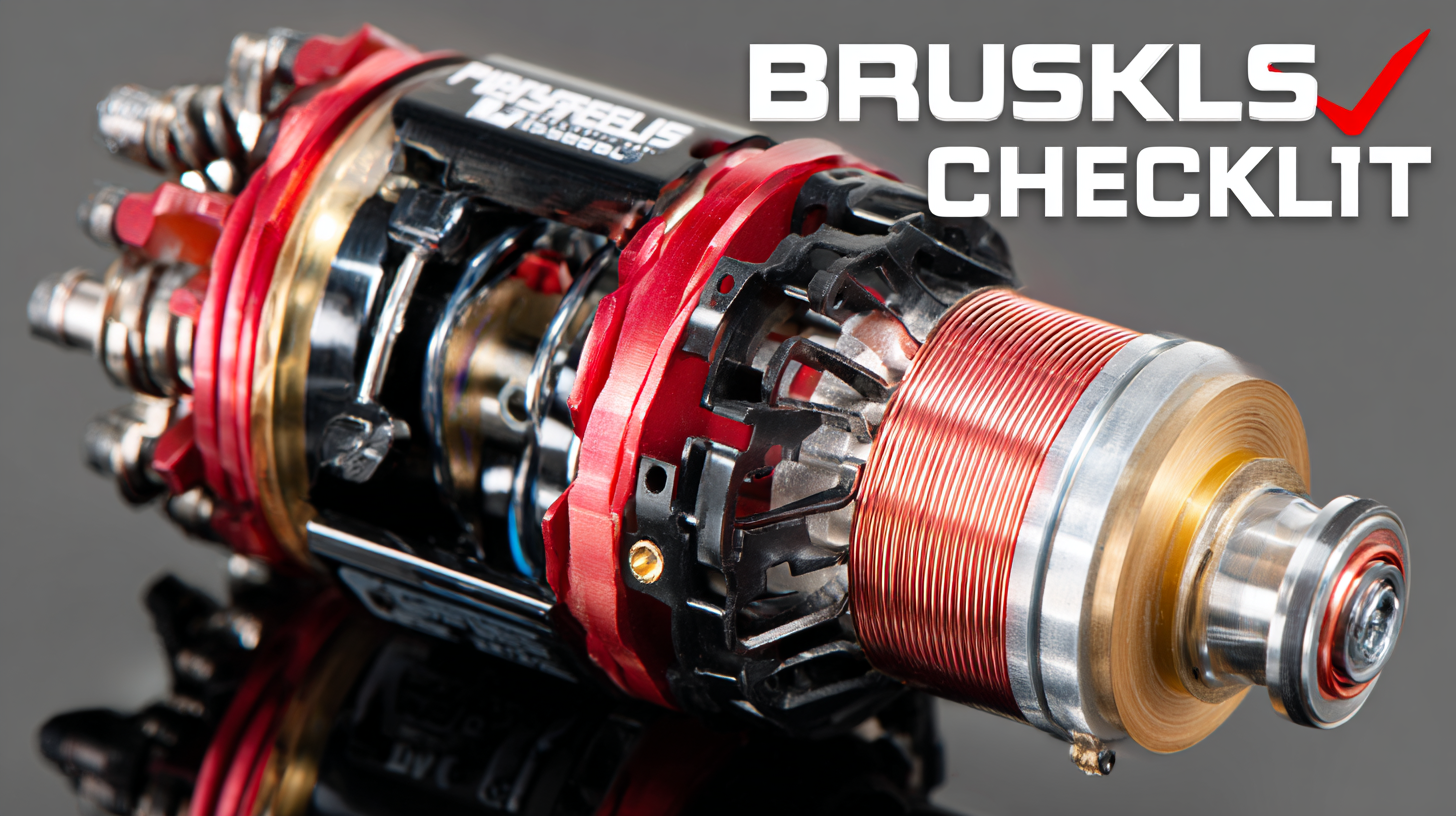

This blog will provide you with an ultimate checklist to make an informed decision in choosing the best brushless motor tailored for your specific needs.

Brushless motors have become increasingly prevalent in various applications, from electric vehicles to consumer electronics, due to their efficiency and reliability. Unlike traditional brushed motors, brushless motors operate without physical brushes, leading to reduced friction and wear. This construction results in longer service life and increased performance, making them preferable in sectors where reliability is paramount. According to a report by MarketsandMarkets, the global brushless motor market is projected to reach $15.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.0%, underlining the growing trend towards adopting this technology.

When selecting a brushless motor, it's essential to understand key specifications such as torque, speed, and efficiency. For instance, the motor's torque is crucial for applications requiring high load capacity, while the speed is vital for operations demanding rapid movement. The efficiency of brushless motors can reach up to 90%, significantly higher than traditional models, leading to lower energy consumption. A study published in the IEEE Transactions on Industrial Electronics indicates that the reduction in energy costs can be as much as 30% when switching from brushed to brushless motors, making them an economically advantageous choice for both small and large-scale applications.

When selecting a brushless motor for your application, understanding the power requirements is crucial. Begin by determining the operational voltage and the current demands across different load conditions. This involves calculating the torque needed for your specific task, as the motor's performance is directly linked to its ability to handle load efficiently. For example, higher torque values during startup may necessitate a motor with a higher current capacity. Knowing your application's power requirements allows you to filter motor specifications that will provide optimal performance without risking burnout or inefficiency.

Another vital aspect to consider is the power-to-weight ratio of the motor. In applications where weight is a constraint, such as in drones or handheld tools, choosing a lightweight motor that still offers adequate power output is essential. Evaluate motors rated for continuous operation compared to those rated for intermittent use, depending on how your project will utilize the motor. By aligning the motor specifications with the unique demands of your application, you ensure not only operational efficiency but also longevity and reliability in performance.

When it comes to selecting the right brushless motor for various applications, understanding key performance and efficiency features is crucial. Brushless motors are renowned for their high efficiency, often exceeding 90% in optimal conditions. According to a report from the International Journal of Electrical and Electronics Engineering, brushless DC (BLDC) motors can deliver superior torque-to-weight ratios, which makes them ideal for applications ranging from drones to electric vehicles.

One important feature to consider is the motor's operational speed. Brushless motors generally operate at higher RPMs and can maintain consistent performance under load. Additionally, the type of electronic speed controller (ESC) used can significantly influence motor efficiency. A high-quality ESC can reduce energy losses and enhance response times, leading to improved overall system performance.

Tips: When evaluating brushless motors, look for those with high thermal management capabilities, as they prevent overheating and prolong motor life. Additionally, consider models with low cogging torque for smoother operation, which is especially beneficial in applications requiring precise movement.

When it comes to selecting a brushless motor for your application, understanding the balance between cost and value is crucial. The initial price tag of a motor often reflects its performance capabilities, durability, and efficiency. While it may be tempting to opt for the lowest-cost option, it’s essential to consider how that choice aligns with the specific requirements and long-term goals of your project. Investing a little more upfront in a high-quality brushless motor can lead to significant savings in maintenance, energy consumption, and overall operational efficiency over time.

Budgeting for a brushless motor shouldn't just focus on the purchase price; it's important to account for additional factors such as installation, maintenance, and the potential need for complementary components. A comprehensive evaluation of these costs will help you determine the true value of a motor for your application. It’s wise to conduct thorough research and possibly consult with industry experts. By assessing your needs against the backdrop of your budget, you can make an informed decision that not only meets your immediate requirements but also enhances the overall performance and reliability of your system in the long run.

When it comes to ensuring the longevity of your brushless motor’s performance, regular troubleshooting and maintenance are key. It's essential to create a routine that includes checking connections and components for wear and tear. Regularly inspect the electrical connections and wiring for any signs of corrosion or loose fittings, as these can lead to inefficient operation and reduced lifespan of your motor.

Furthermore, keeping the operating environment clean is crucial. Dust and debris can accumulate in and around the motor, leading to overheating and potential damage. To prevent this, consider using protective enclosures and ensuring proper ventilation. A simple tip is to schedule periodic cleanings which will not only enhance motor performance but also help in early detection of potential issues.

Lastly, don’t overlook the importance of software updates for motors equipped with electronic speed controllers (ESCs). These updates can improve efficiency, fix bugs, and sometimes even add new features to your existing system. Regularly check for updates and make it part of your maintenance routine to reap the full benefits of your brushless motor and extend its service life.