In the rapidly evolving landscape of global supply chains, sourcing the best BLDC (Brushless Direct Current) motor has become increasingly complex due to hidden challenges associated with industry-specific import and export certifications. According to a recent market research report, the global BLDC motor market is projected to reach USD 30 billion by 2025, driven by the growing demand for energy-efficient solutions across various sectors, including automotive and consumer electronics.

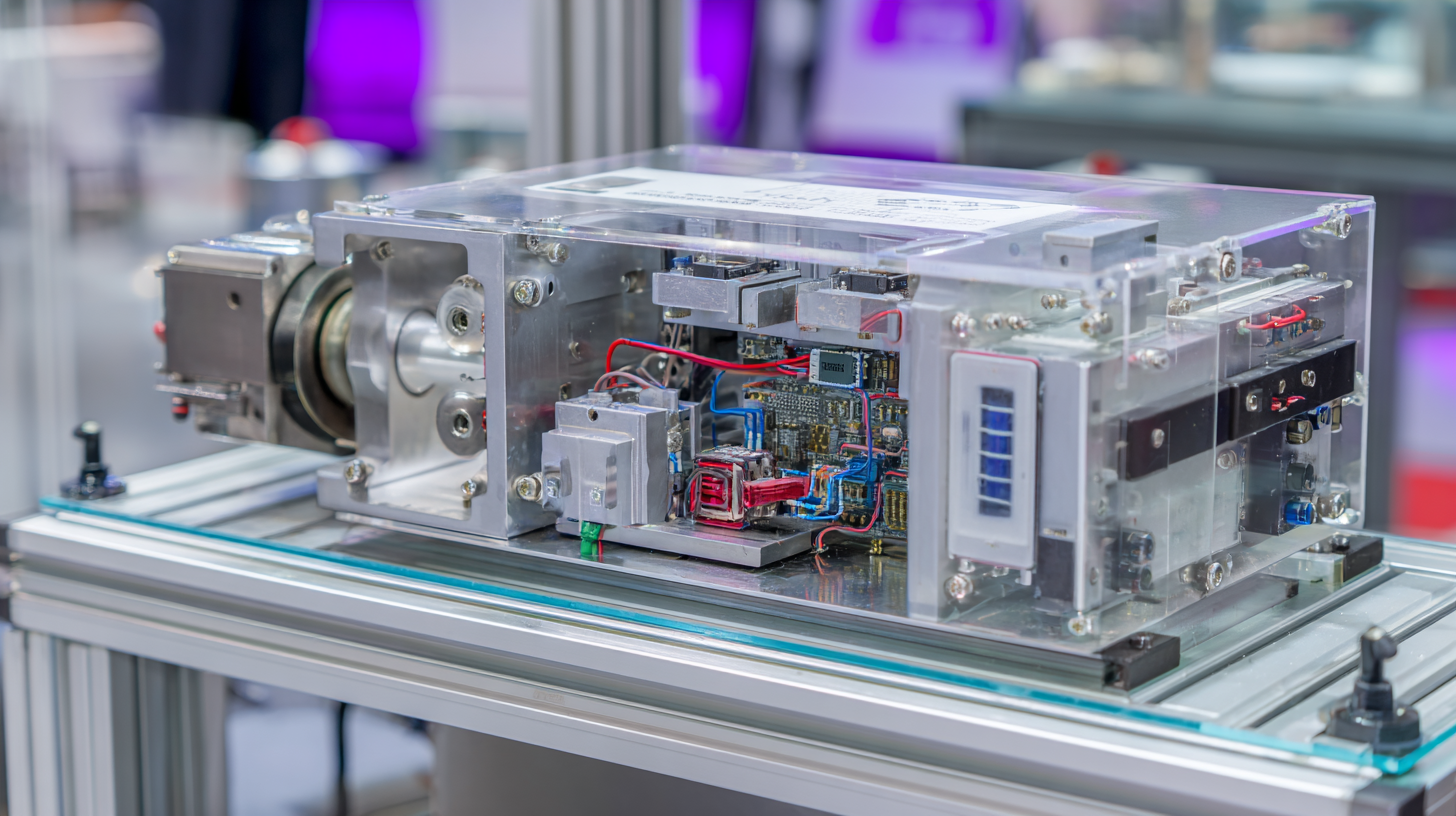

However, navigating the intricate web of regulatory requirements presents significant obstacles for manufacturers and suppliers alike. With the introduction of stringent certification processes, businesses must adapt quickly to remain competitive while ensuring compliance with local and international standards. This blog delves into these hidden challenges and explores how leveraging digital tools and recognizing top-tier motor types can facilitate better sourcing strategies in an increasingly regulated environment.

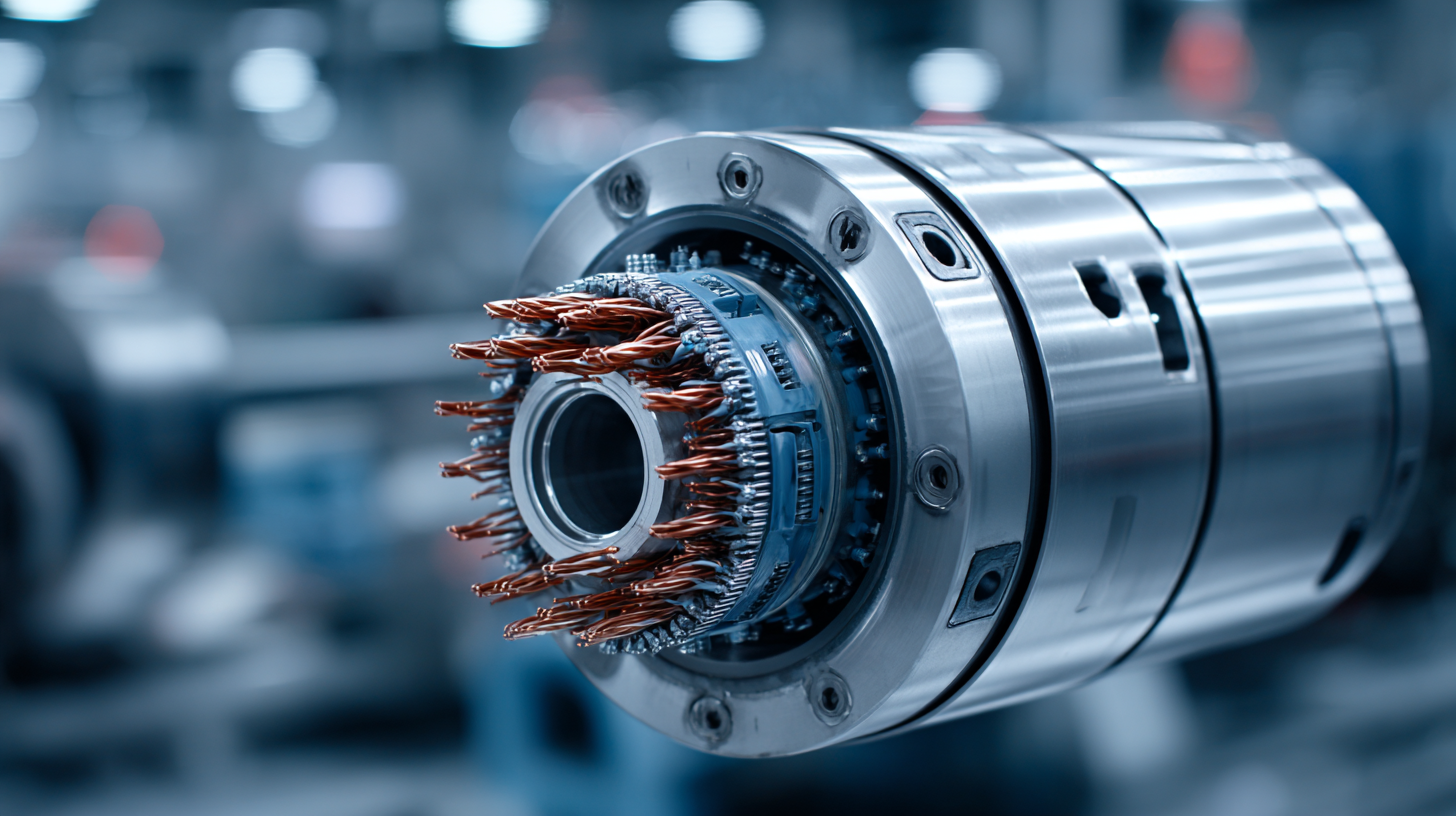

Brushless DC (BLDC) motors play a pivotal role in modern global supply chains, serving as the powerhouse behind various essential applications, from automotive systems to industrial automation. According to a report by Research and Markets, the BLDC motor market is projected to reach USD 17.20 billion by 2026, growing at a CAGR of 8.3% from 2021. This robust growth is driven by the increasing demand for energy-efficient solutions and the push towards automation across industries. The significance of BLDC motors is heightened in supply chains where efficiency and reliability are paramount, especially as manufacturers seek to enhance the speed and accuracy of their operations.

Furthermore, the importance of BLDC motors extends beyond their operational benefits; they are integral to sustainability initiatives within supply chains. As per a study by McKinsey, companies leveraging energy-efficient technologies, such as BLDC motors, can reduce their operational carbon footprint by up to 30%. This aligns with the growing pressure on businesses to adopt greener practices due to regulatory requirements and consumer expectations. Therefore, sourcing the best BLDC motors not only ensures operational excellence but also supports corporate sustainability goals, making them vital components in the evolving landscape of global supply chains.

Sourcing the best Brushless DC (BLDC) motor for global supply chains presents a set of unique challenges that companies must navigate carefully. One of the primary factors influencing BLDC motor sourcing is the technological specificity required for different applications. Various industries demand motors with distinct performance attributes like torque, speed, and efficiency, necessitating a thorough understanding of the unique needs of each application before selecting a supplier.

Another critical consideration is the supplier's geographical location and its impact on lead times and logistics. As businesses seek to optimize their supply chains, proximity to manufacturing hubs can significantly affect operational efficiency and cost. Additionally, geopolitical factors, trade regulations, and potential tariffs can introduce uncertainties that make sourcing decisions even more complex. Companies must also accentuate the importance of building strong relationships with suppliers to ensure reliability and quality, as not all manufacturers may meet the industry's stringent standards. By carefully evaluating these key factors, organizations can better position themselves to overcome the hidden challenges in BLDC motor sourcing.

| Factors | Importance Level (1-5) | Challenges | Potential Solutions |

|---|---|---|---|

| Performance Specifications | 5 | Variability in performance metrics | Standardize specifications with suppliers |

| Cost Competitiveness | 4 | Fluctuating component costs | Negotiate long-term contracts |

| Lead Time | 4 | Longer shipping times | Implement regional suppliers |

| Quality Control | 5 | Inconsistent quality assurance | Introduce strict quality audits |

| Supplier Reliability | 5 | Risk of supplier insolvency | Diversify supplier base |

| Technological Advancement | 4 | Lack of innovative features | Invest in R&D partnerships |

When evaluating BLDC motors for global supply chains, understanding the performance metrics among leading manufacturers is crucial. Different manufacturers implement various strategies to reduce radial forces and enhance overall efficiency. For instance, examining the rotor design and material selection can reveal how some manufacturers achieve lower vibrations and improved torque delivery, ultimately contributing to a more reliable and longer-lasting motor.

When evaluating BLDC motors for global supply chains, understanding the performance metrics among leading manufacturers is crucial. Different manufacturers implement various strategies to reduce radial forces and enhance overall efficiency. For instance, examining the rotor design and material selection can reveal how some manufacturers achieve lower vibrations and improved torque delivery, ultimately contributing to a more reliable and longer-lasting motor.

Tip: When comparing BLDC motors, focus on specific performance metrics such as efficiency ratings, torque-to-weight ratios, and thermal performance. These aspects often indicate how well a motor will perform in real-world applications.

Additionally, improved design features, such as optimized magnet placement and advanced winding techniques, can significantly influence the motor's effectiveness. Some manufacturers may offer custom solutions tailored to unique application needs, which can further distinguish their offerings.

Tip: Always request detailed specifications and performance data from manufacturers to ensure a comprehensive understanding of their motor capabilities and how they might meet your supply chain requirements.

Evaluating the cost-effectiveness and lifecycle of Brushless DC (BLDC) motors is crucial for companies navigating the complexities of global supply chains. According to a recent report by MarketsandMarkets, the BLDC motor market is projected to reach $22.11 billion by 2026, growing at a CAGR of 9.1%. This growth is driven by industries recognizing the energy efficiency and reduced maintenance costs associated with BLDC motors compared to traditional brushed motors. Specifically, BLDC motors can be up to 90% more efficient, leading to significant savings over their operational lifespan.

In addition to immediate cost savings, evaluating the entire lifecycle of BLDC motors can reveal long-term benefits. A study by the Electric Power Research Institute (EPRI) indicates that the total lifecycle cost of a BLDC motor, factoring in energy consumption, maintenance, and disposal, can be as much as 30% lower than that of traditional motors. This underscores the importance of a comprehensive evaluation approach when sourcing motors for supply chains—companies that prioritize lifecycle assessments are better positioned to maximize their investment and enhance their sustainability profiles in an increasingly competitive market.

When sourcing BLDC motors for global supply chains, organizations often face a myriad of risks and challenges that can impact procurement success. One of the primary concerns is supplier reliability. Many manufacturers may not have a proven track record, leading to potential delays in delivery or issues with product quality. Conducting thorough due diligence and establishing strong partnerships with reputable suppliers can mitigate these risks, ensuring a more stable supply chain.

Additionally, fluctuations in material costs and availability can pose significant difficulties. The prices of raw materials used in manufacturing BLDC motors can be volatile, influenced by market demand and geopolitical factors. Companies need to implement strategic sourcing practices and consider hedging options to buffer against these fluctuations. Furthermore, understanding the regulatory environments across different regions is crucial. Compliance with local and international standards can complicate the procurement process, adding another layer of complexity that businesses must navigate carefully. By identifying these common challenges, companies can better prepare for a successful procurement strategy that addresses potential pitfalls in their supply chains.